Innovation. Infrastructure. Industry.

Investing in our Future

Investments in technological infrastructure keep CALS on the forefront of innovation. Not only do NC State and NCDA&CS provide agricultural land and resources to researchers, but they also support the budding ag tech industry in North Carolina. Recent tech upgrades to CALS’ Reedy Creek Educational Units have opened up new possibilities for an industry partnership.

Hoofprint Biome, a startup headquartered in the NC State Plant Sciences Building, is developing probiotics and natural enzymes to improve cattle gut health and reduce methane emissions. Cattle contribute 6% of global greenhouse gas emissions.

To achieve those goals, Hoofprint Biome needed a facility capable of supporting detailed data monitoring and bovine management. The Reedy Creek Educational Units fit the bill but required significant updates to their digital infrastructure.

Cattle contribute 6% of global greenhouse gas emissions.

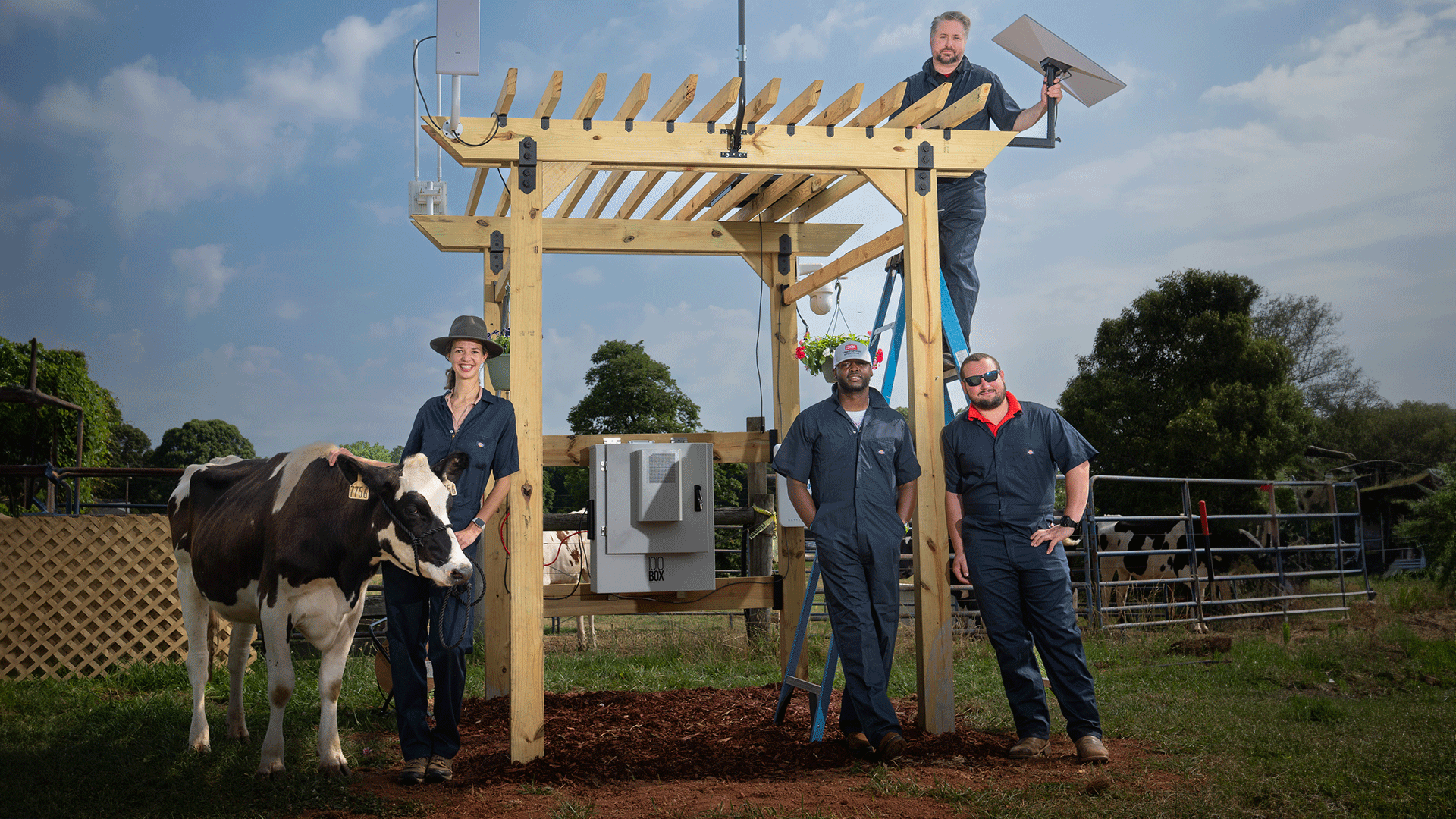

Following a similar model as the research stations and field labs, Jevon Smith and Trevor Quick dug a trench to lay fiber optic cables, then built a pergola to house SpaceX-Starlink servers for high-speed internet access alongside data processing technology.

“There’s a lot of potential in this private sector partnership that really highlights the importance of our continued investment in connectivity,” Smith says. “Without it, none of this would be possible.”

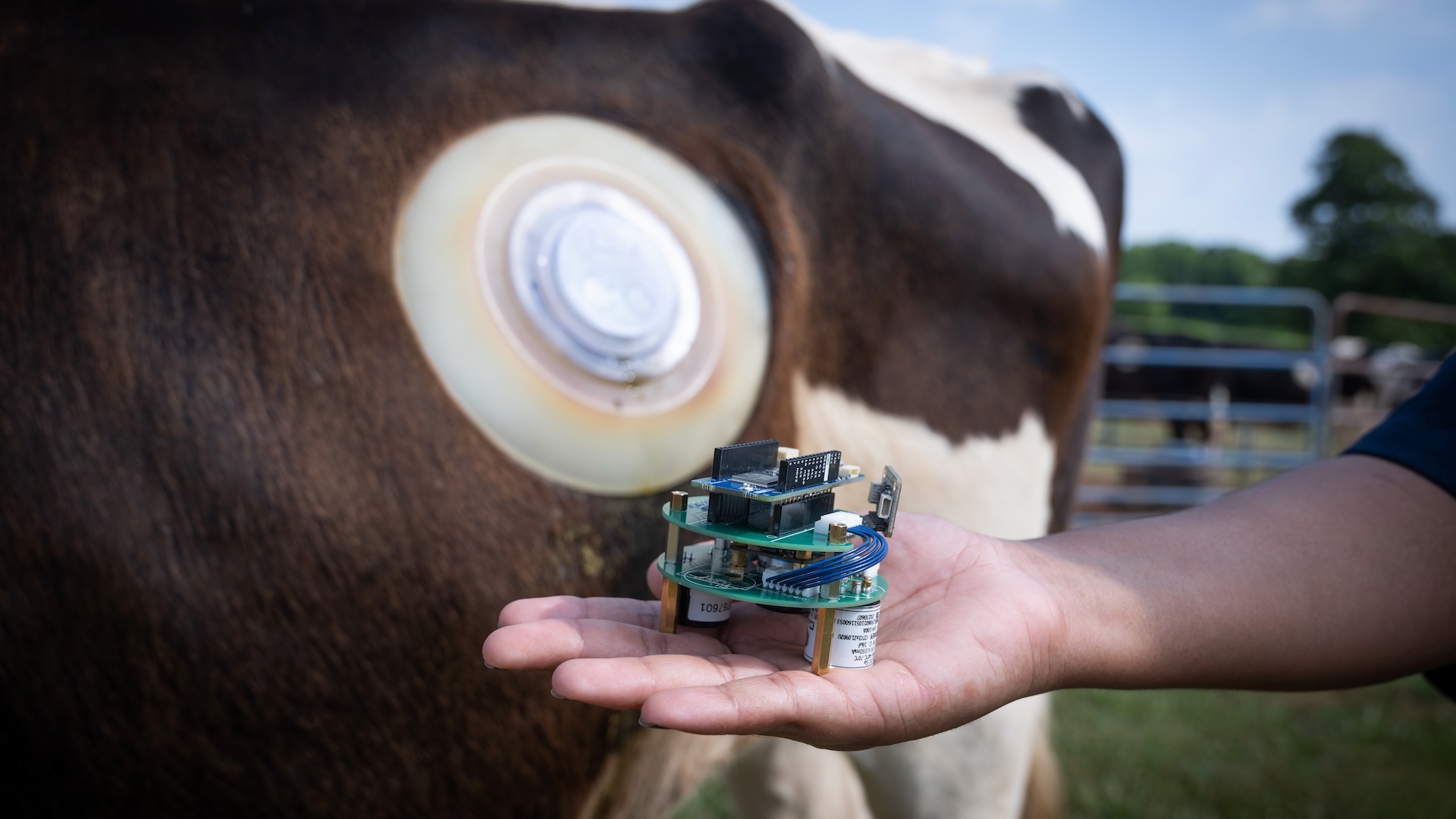

With the newly installed equipment, Hoofprint Biome can collect real-time data using sensor technology developed in the N.C. PSI Makerspace. The device measures the hydrogen, CO² and methane in each cow’s gut via a portal-like attachment. Every 30 minutes, data from the cow’s gut is sent to a computing data processor housed on the pergola and uploaded to the cloud. Hoofprint Biome will use that information to measure the effectiveness of their nutritive solutions.

“I can now log into my laptop from anywhere to monitor methane concentration continuously from each of the cows wandering in the pasture,” says Kathryn Polkoff, co-founder and CEO of Hoofprint Biome. “This capability is something that sets NC State apart from anywhere in the world.”

- Categories: